Brian Boru Boot Size 8

Instep view of the Gaelic 'Brian Boru' Boot taken in the display area of my workshop - this series of pictures were taken by Paul Fox, thanks Paul. At the top of the boot you can see my unique 'Maker's Mark' or personal logo in Ogham inside the outline of a shoe/boot shape - it reads 'conmade'.

Outside of the right boot and heel of the left boot. A combination of finishing layers including Mink Oil, Dark Tan dye and Brown shoe polish combine to give a variegated mahogany color - this will darken further with polishing and age.

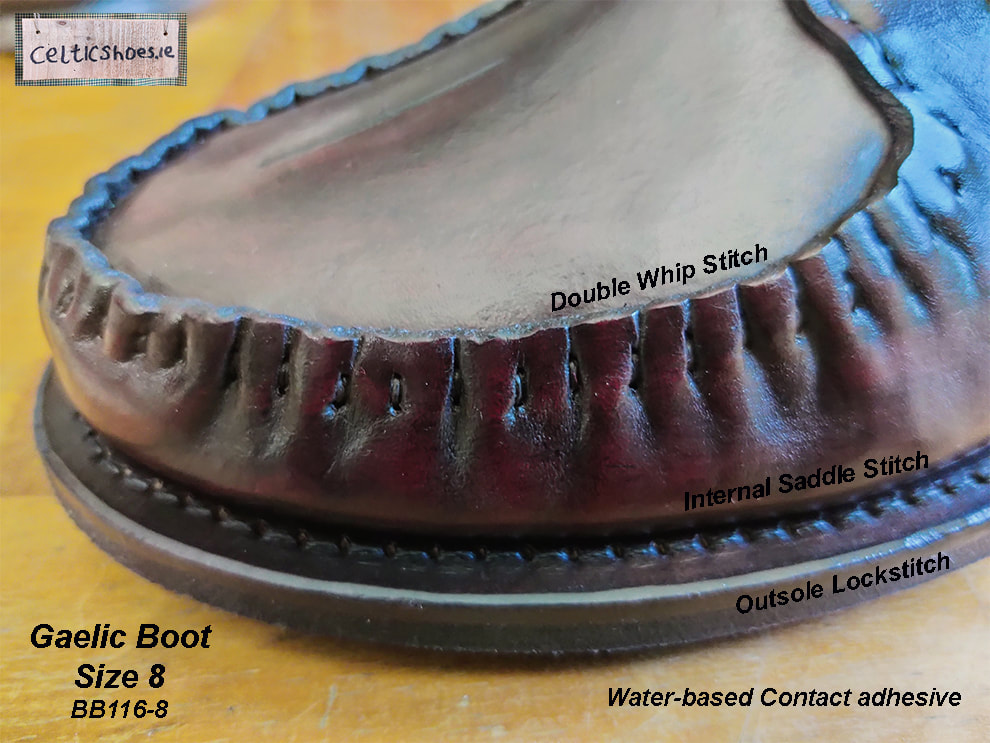

The vamp or top of the toe area is sewn to the upturned toe with a double whipstitch using braided waxed thread facilitating better waterproofing. The leather upper is sewn to the leather midsole with a saddle stitch of waxed thread. The rubber outsole is sewn to the midsole welt with a lockstitch. All sewing is done by hand.

The white thread inside the leather upper shows how I join the upper to the leather midsole with a saddle stitch of waxed thread. Before sewing I stick the two parts together with water based contact adhesive. Each pair of shoes and boots I make have a unique numbering identifier stamped on the inside of the leather upper. The line of stitches under the 'BB116-8' is how I create the instep support for each foot using waxed thread and double whip stitching.

The high quality studded rubber outsole and heel are a modern industry standard. Both sole and heel are glued using water based contact adhesive. The sole is fully sewn (i.e. 360*) to the midsole using waxed thread. The heel is glued and finally secured using 20mm copper nails. Flexible and hard wearing - this allows resoling many times.

The back of the Gaelic Boot displays the clever engineering of the cut out shape that the Gaelic Boot makers used during the Brian Boru era. The heel pinch creates a heel cup to hold and surround the upper heel. It also creates extra space around the ankle bone on both sides. The folded heel tab creates a heel thickness of 4.2mm stiffening the back of the heel cup so the back of the boot does not sag with age. The 3mm veg tan leather midsole is the equivalent of a full welt sole. The studded rubber outsole is fully 360* sewn to the leather midsole. The studded rubber heel block is fixed with water based contact adhesive and copper nails.

The shape is formed by hand during the cut out and sewing processes, the drying and conditioning processes secure that shape into its planned finish, then it is polished using the same polish as in the Owners Care Kit. But - getting any shoes or boot damp or wet will change their shape - to get long term pride of ownership = use the shoe trees when you are not wearing your boots.

If the shoe trees are not in your boots it is because the boots are on your feet.

The cedar wood shoe trees remove odour while adding a freshness, they remove dampness and they help maintain the designed shape of the boot too. On the outside of each boot above the ankle you can see my 'Maker's Mark' or personal logo - this also appears on the modified pull strap of the cedar wood shoe tree. The polish has Mink Oil in it and was chosen because the conditioning after the boot was created used 100% Mink Oil to keep these boots soft, supple and water resistant too. You may not need the shoe horn until you are wearing thick socks and then it can help to get a snug fit with ease.

Prices from €1250 for 'made to order' (in stock / off the shelf) and from €1450 for 'made to measure' bespoke versions.